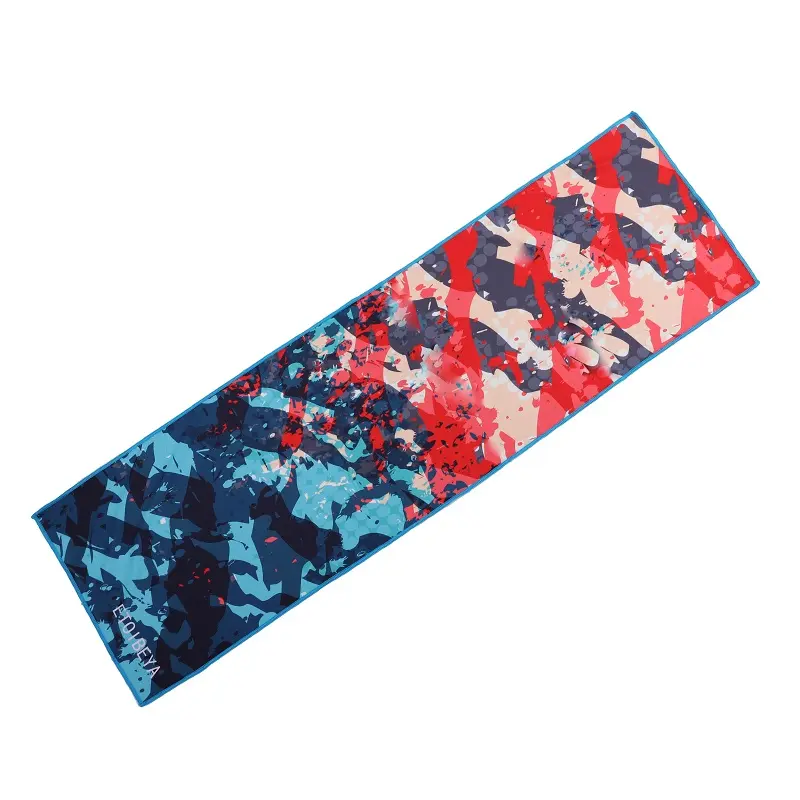

custom beach towel factory

A custom beach towel factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality, personalized beach towels at scale. These facilities combine traditional textile expertise with modern manufacturing technologies to create customized beach towels that meet diverse client specifications. The factory utilizes advanced digital printing equipment capable of reproducing intricate designs and vibrant colors on premium cotton and microfiber materials. The production line typically features automated cutting and sewing stations, quality control checkpoints, and sophisticated material handling systems. The facility's capabilities extend to various customization options, including different sizes, materials, weights, and design complexities. Modern custom beach towel factories incorporate sustainable practices, such as water recycling systems and eco-friendly dye processes, while maintaining efficient production schedules. They typically house dedicated departments for design consultation, sample creation, bulk production, and quality assurance. The factory's infrastructure supports both small custom orders and large-scale production runs, with specialized areas for material storage, production, packaging, and distribution. These facilities often feature in-house testing laboratories to ensure product durability, color fastness, and absorption properties meet international standards.